Application:

Liquid Metal veneer appears to be almost as simple to use as paint, however, it is not paint and certain rules need to be observed. The liquid metal can be applied using brush or high volume, low-pressure spray equipment. The liquid metal may also be poured or troweled onto surface and used for cold metal casting or patterning.

Coverage Guide:

Approximately one meter square per one kilogram of metal veneer liquid is applied depending on the absorbency and texture of the base material. The more textured the finish, the more liquid material is required. After application, the liquid metal coating will take between one to three hours to dry depending on humidity and room temperature.

Finishing:

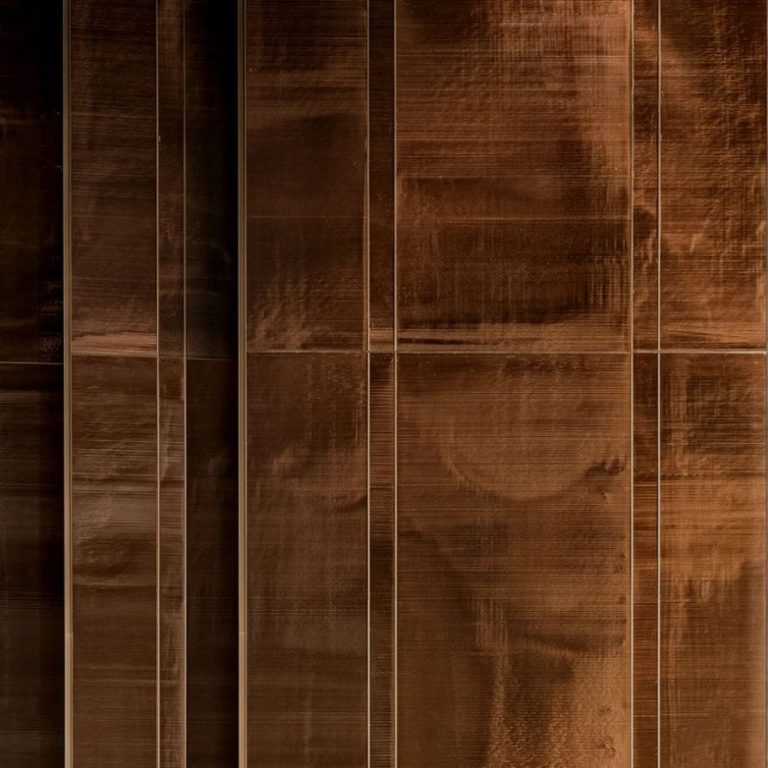

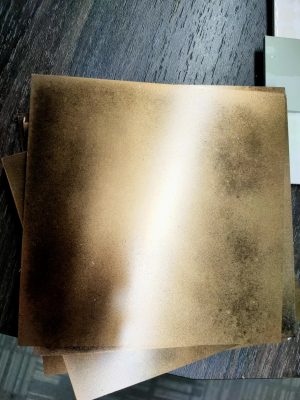

When liquid metal veneer dries, it will have a matte finish due to oxidization that occurs after contact with the air. Lightly sanding the surface will produce a pure metal finish. Further efforts of sanding and/or polishing will produce ever increasing grades of shine and luster that provide exciting metal finish possibilities. Other creative processes can be applied such as acid wash, patina wash, sandblast, wire brush and machined textures. Customers are encouraged to experiment with the liquid metal coating for all sorts of creative metal applications.

Sealing:

As with any real metal, it must to be sealed to prevent tarnishing (unless a finish that continues to patinate over time is desired). Metals may be sealed with Nano-Coating, hard wax oil, or a clear coat urethane.

Luxface has trained a team of highly skilled artisans specializing in the application of real metal finishes to virtually any substrate; custom coatings and finishes available. Please contact or visit us to begin imagining your ideas into finished metal design.