Acrylic vs. plexiglass: what’s the real difference? Both materials, glass discriminating plexiglass and acrylic glass, are popular for their clarity and versatility, but they have unique properties that set them apart, including significant advantages acrylic and plexiglass polycarbonate. Acrylic, also known as plexiglas, is lightweight and shatter-resistant like glass, making it ideal for various applications such as plates and other product uses. Plexiglass sheets, often used interchangeably with acrylic plates, offers enhanced durability and UV resistance, perfect for outdoor use.

Understanding these differences can help you choose the right material, such as acrylic sheeting, acrylic plexiglass, plates, or extruded acrylic sheets, for your project. Whether you’re crafting a display case or building a greenhouse, knowing the pros and cons of each will save you time and money. Dive in to discover which option, such as glass, plates, plexiglas, or acrylic sheet, suits your needs best.

Key Takeaways

- Acrylic and plexiglass are often used interchangeably, but acrylic is a type of plastic, while Plexiglass is a brand name for acrylic sheets. Understanding this can help you choose the right material for your project.

- Both materials, glass and plexiglas, are lightweight and shatter-resistant, making them ideal for safety applications like acrylic sheet. Consider using plexiglas in places where glass might break easily.

- When thinking about safety and environmental impact, remember that acrylic can be recycled, but not all plexiglass products are recyclable. Check local recycling guidelines before disposal.

- Different industries use acrylic and plexiglass for various purposes, such as signage, displays, and protective barriers. Identify which glass applications best suit your needs based on these plexiglas examples.

- Regular maintenance is key to keeping acrylic and plexiglass clear and scratch-free. Use mild soap and water for cleaning glass and plexiglas to avoid damaging the surface.

- Knowing the differences in properties of glass and plexiglas can help you make informed decisions when purchasing materials for projects. Always compare specific features like UV resistance and clarity based on your requirements.

Understanding Acrylic and Plexiglass

Definition and Differences

Acrylic and plexiglass are both forms of polymethylmethacrylate (PMMA). The term “acrylic” refers to the chemical name. On the other hand, “plexiglass” is a trade name. It is important to note that Plexiglas® is just one brand of glass among many. Other brands include Lucite®, Acrylite®, and Perspex®. These names can often lead to confusion but refer to similar materials like glass and plexiglas, with slight differences in quality or properties.

Historical Background

The development of acrylic materials, including plexiglas and glass, began in the early 20th century. Scientists first created acrylic compounds in the 1920s. By the late 1930s, Plexiglas® became prominent during World War II. It was used for aircraft windows due to its lightweight and shatter-resistant properties, including glass and plexiglas. After the war, industries started using acrylic, also known as plexiglas, in various applications including glass. Over the decades, it found its way into signs, displays, and even aquariums. Today, acrylic products are common in everyday life.

Manufacturing Process

Two main processes create acrylic sheets, also known as plexiglas: cell casting and extrusion, similar to glass. Cell casting produces high-quality acrylic sheets. This method involves pouring a glass liquid mixture into molds, allowing it to harden slowly.

Extrusion creates uniform plexiglass sheets. In this process, raw materials are heated until they become a thick liquid. Then, this liquid is forced through a die to form sheets. Heat and catalysts play crucial roles in polymerization during both methods. They help transform the liquid into solid acrylic or plexiglass sheets.

Key Characteristics

Strength and Durability

Plexiglass shows impressive impact resistance compared to traditional glass. It can withstand physical stress without shattering. This quality makes it suitable for applications that need robust materials. For example, safety barriers often use plexiglass because it resists breakage during accidents.

Plexiglass is also lighter than glass, which adds to its durability. The material does not easily scratch or dent, making it ideal for high-traffic areas. This strength ensures that plexiglass remains intact in tough environments.

Clarity and Light Transmission

Acrylic stands out for its superior light transmission, surpassing that of glass. It allows over 92% of visible light to pass through. This optical clarity makes acrylic perfect for lenses and displays. Many manufacturers prefer acrylic for products needing high transparency.

Its clear surface enhances the visibility of items behind it. Acrylic’s clarity is essential in applications like aquariums and signage. Users appreciate how acrylic maintains a bright appearance even after years of use.

Flexibility and Malleability

Heating plexiglass enables easy shaping into various forms. This flexibility allows designers to create custom designs and complex shapes. Industries that require versatile materials benefit from this property.

For instance, artists often use heated plexiglass to produce unique sculptures. Manufacturers also shape plexiglass for automotive parts and lighting fixtures. Its malleability leads to innovative designs that would be difficult with more rigid materials.

UV Resistance

Acrylic demonstrates excellent resistance to UV light, preventing yellowing over time. This property is crucial for outdoor applications where sunlight exposure is common. Unlike some plastics, acrylic does not degrade when exposed to UV rays.

The durability of acrylic in outdoor settings helps maintain its appearance. Users find that it retains its clarity and color much longer than other materials. This advantage makes acrylic a preferred choice for patio furniture and outdoor signage.

Safety and Environmental Impact

Safety Considerations

Plexiglass offers shatter-resistant properties. This makes it a safer choice in many settings. When broken, it does not shatter into sharp pieces like glass. Instead, it cracks but remains mostly intact. This feature reduces the risk of injuries in homes, schools, and workplaces.

Its lighter weight is another advantage. If plexiglass breaks, the chances of severe injury decrease. Lighter materials are easier to handle and install. Plexiglass is widely used in safety barriers and protective equipment. For instance, it is common in sneeze guards and face shields during health crises.

Environmental Impact

The production of acrylic is energy-intensive. It requires significant resources to manufacture. This process can lead to chemical emissions that harm the environment. Acrylic production often involves fossil fuels, contributing to greenhouse gases.

Many companies recognize these concerns. They are working on developing more sustainable production methods. Innovations include using renewable energy sources and reducing waste during manufacturing. These efforts aim to lessen the environmental footprint of acrylic.

Recyclability

Recycling acrylic materials presents challenges. Many recycling facilities do not accept them due to their complex structure. This leads to increased waste in landfills.

However, initiatives are underway to improve recycling processes for acrylic products. Some organizations focus on creating better systems for collecting and processing acrylic waste. These improvements are essential for enhancing recyclability.

Responsible disposal of acrylic is crucial for environmental health. Consumers should seek local recycling options or programs that accept acrylic materials. Proper recycling helps reduce pollution and conserves resources.

Applications in Various Industries

Construction and Architecture

Acrylic is widely used in construction. It serves as an excellent material for skylights and windows. These installations allow natural light to flood into buildings. Many modern architectural designs incorporate acrylic for its sleek appearance. It creates durable and aesthetic building elements. Architects appreciate its ability to withstand harsh weather while maintaining clarity.

The lightweight nature of acrylic makes it easy to handle during installation. This reduces labor costs and speeds up project timelines. Its versatility allows for creative shapes and sizes, enhancing the overall design of structures.

Signage and Displays

Acrylic shines in the signage and display sector. Its clarity ensures vibrant colors stand out. Businesses use acrylic for point-of-sale displays and advertising materials. The material can be easily shaped and printed on, making it highly effective for marketing.

Durability is another key feature of acrylic. It holds up well in high-traffic areas, resisting scratches and impacts. This longevity means businesses save money on replacements. Acrylic signs remain attractive over time, drawing customers’ attention.

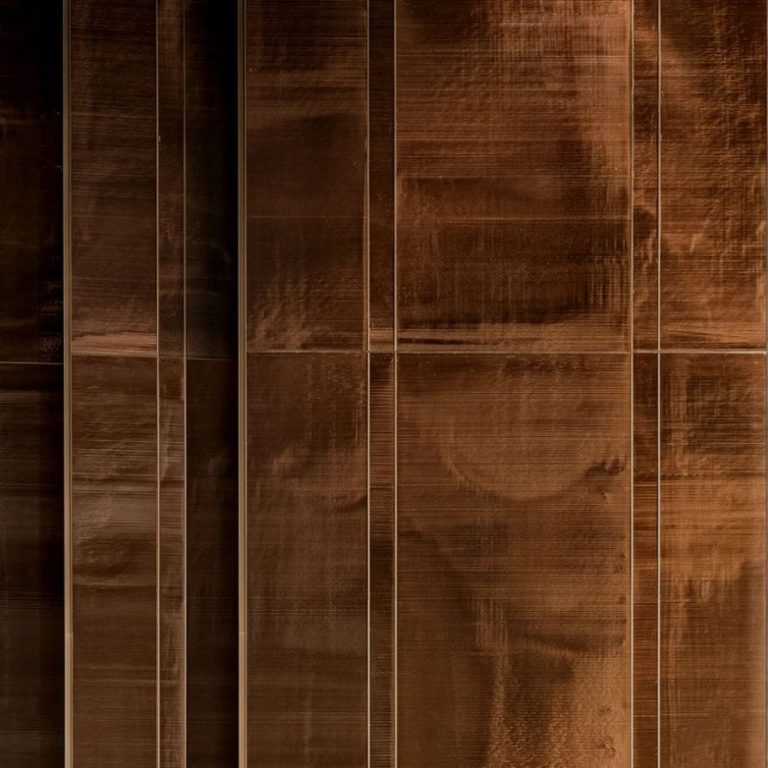

Art and Design

Artists favor acrylic for its versatility. The material is popular for creating sculptures and installations. It can be colored, textured, or molded into various shapes, allowing for endless creativity.

Many artists appreciate how light interacts with acrylic. It can create stunning visual effects that enhance their work. The ability to combine different colors adds depth to projects. Artists often choose acrylic for both indoor and outdoor installations due to its durability.

Automotive and Medical Uses

Acrylic plays a crucial role in the automotive industry. Manufacturers use it in vehicle windows and windshields. Its lightweight nature helps improve fuel efficiency without sacrificing safety.

In the medical field, acrylic is essential for various devices and equipment. It provides clarity in medical screens while being easy to sanitize. Hospitals rely on acrylic for durable components that can withstand regular cleaning.

The combination of strength and lightness makes acrylic ideal for these applications. It enhances performance while ensuring safety in vehicles and medical settings.

Maintenance and Care Tips

Cleaning Techniques

Acrylic surfaces require special attention for cleaning. Use a soft cloth and mild soap to clean them. This method helps avoid scratches that can occur with harsher materials. Never use abrasive cleaners or scrubbers. They can damage the surface, leaving permanent marks. Regular maintenance is key to keeping acrylic clear and attractive. Clean it often to prevent dirt buildup. This practice will help maintain its clarity over time.

Repairing Damages

Minor scratches on acrylic can often be buffed out easily. Use a fine polishing compound for this task. Apply it gently with a soft cloth in circular motions. For deeper damages, consider using an acrylic repair kit. These kits usually include adhesive and tools specifically designed for fixing acrylic. They can restore the material’s appearance effectively. However, significant issues may need professional repairs. Professionals have the expertise to handle complex damages without causing further problems.

Longevity Tips

To extend the life of acrylic products, store them properly. Keep acrylic away from direct sunlight to prevent warping and fading. Sunlight can cause changes in shape and color over time. Regular cleaning also plays a crucial role in longevity. It prevents buildup that can dull the surface and affect clarity. Lastly, consider using protective coatings on acrylic surfaces. These coatings enhance durability and provide an extra layer of protection against scratches and UV light.

Final Remarks

Acrylic and plexiglass both have unique benefits that make them suitable for various applications. Understanding their key characteristics helps you choose the right material for your projects. Safety and environmental impact are crucial factors to consider, ensuring you make responsible choices. Maintenance tips can extend the life of your materials, saving you time and money in the long run.

Now that you’re equipped with this knowledge, it’s time to take action. Whether you’re designing a display, creating art, or tackling a DIY project, using the right material can enhance your results. Dive deeper into your options and make informed decisions that suit your needs. Your next project awaits!

Frequently Asked Questions

What is the difference between acrylic and plexiglass?

Acrylic is a type of plastic, while Plexiglass is a brand name for acrylic. Both materials offer similar properties but may differ in quality and clarity depending on the manufacturer.

Is acrylic or plexiglass more durable?

Both materials are highly durable. However, high-quality Plexiglass often has superior impact resistance compared to standard acrylic sheets, making it a preferred choice for demanding applications.

Can you use acrylic and plexiglass outdoors?

Yes, both acrylic and Plexiglass are UV-resistant and suitable for outdoor use. They maintain clarity and strength even when exposed to sunlight over time.

How do I clean acrylic or plexiglass?

Use a soft cloth and mild soap solution for cleaning. Avoid abrasive cleaners or tools, as they can scratch the surface and diminish clarity.

Are acrylic and plexiglass safe for food contact?

Food-safe grades of acrylic exist, but standard plexiglass should not be used for food contact without confirmation from the manufacturer. Always check for FDA compliance.

What industries commonly use acrylic and plexiglass?

Both materials are widely used in various industries, including signage, automotive, construction, and healthcare due to their versatility and aesthetic appeal.

How can I repair scratches on acrylic or plexiglass?

Minor scratches can often be buffed out using a fine polishing compound. For deeper scratches, consider professional refinishing or replacement for optimal results.