What is acrylic glass? This versatile plastic material has become a popular choice for many applications, including flexible plastic, plastic laminate, and acrylic building materials. It’s lightweight, shatter-resistant, and offers excellent clarity. From home decor to industrial uses, plexiglas and plastic acrylic glass is everywhere in a way that requires basic tools.

People love it for its durability and ease of use, especially in applications acrylic like acrylic prints and laminated glass. You can find acrylic prints in windows, signs, and even aquariums. It’s a fantastic alternative to traditional glass. Understanding what acrylic glass is can help you choose the right materials for your projects. Whether you’re a DIY enthusiast or a professional, knowing the benefits of acrylic glass opens up new possibilities. Dive into the world of acrylic glass and discover how it can enhance your life.

Key Takeaways

- Acrylic glass is a versatile material known for its clarity and strength, making it a popular choice for various applications.

- It is lighter and more impact-resistant than traditional glass, which makes it ideal for projects like acrylic sheet applications where weight and durability are important, such as in acrylic prints and uv acrylic uses.

- Consider using acrylic sheets or laminated glass for DIY projects or home improvements, as they can be easily cut and shaped to fit your needs.

- When purchasing acrylic, compare prices and availability at local hardware stores and online retailers to find the best deal.

- Remember that while all acrylic is technically plexiglass, not all plexiglass is branded as such; understanding these terms can help you make informed choices.

- If you have questions about working with acrylic, consult the FAQs section for tips on cutting, cleaning, and maintaining your acrylic glass.

Understanding Acrylic Glass

Definition and Composition

Acrylic glass is a transparent thermoplastic. It is also known as plexiglass. This material is a homopolymer made from methyl methacrylate. Its structure gives the acrylic sheet high impact resistance and excellent optical clarity for acrylic prints.

Acrylic glass is lightweight, making it easy to handle. It also has good UV resistance. These properties make it popular in many applications. You can find it in windows, displays, and even aquariums made of acrylic sheet.

History and Development

The origins of acrylic glass date back to the early 20th century. In 1928, chemists discovered how to create this new acrylic sheet material. The first commercial use came in the 1930s. Over time, more industries began to adopt acrylic glass for various purposes.

Key developments occurred during World War II. The military used acrylic glass for aircraft canopies. This increased its visibility and safety compared to traditional acrylic sheet materials. After the war, advancements in acrylic sheet technology continued to improve its strength and durability.

Technological improvements have also enhanced its properties over time. Manufacturers developed better ways to produce acrylic glass. These methods increased clarity and reduced imperfections. As a result, acrylic glass became more widely used in everyday products.

Differences from Traditional Glass

Acrylic glass stands out when compared to traditional glass. One major difference is impact resistance. Acrylic is 10 times stronger than regular glass. This makes it less likely to shatter on impact.

Weight is another key factor. Acrylic is significantly lighter than traditional glass. This feature makes it easier to transport and install acrylic sheet in various settings.

Safety is an important advantage as well. When acrylic breaks, it tends to fracture with dull edges. This reduces the risk of injury compared to sharp shards from broken glass.

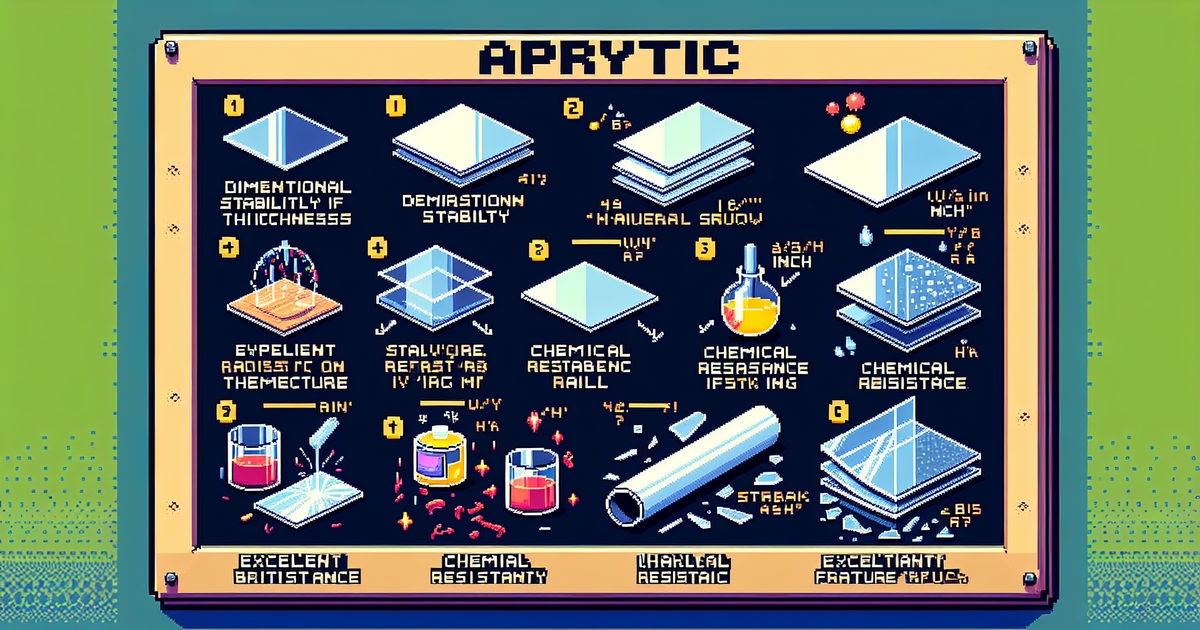

Properties of Acrylic

Physical Characteristics

Acrylic sheets come in various thicknesses. They can range from as thin as 1/16 inch to over an inch thick. This variety allows for a wide range of applications.

Dimensional stability is another key feature of acrylic material. It does not warp or shrink under temperature changes. Weatherability is also impressive; acrylic can resist UV rays and harsh environmental conditions.

Chemical resistance stands out as well. Acrylic can handle many chemicals without degrading. Its durability means it lasts long, making it a preferred choice in many industries.

Durability and Strength

Acrylic has high impact resistance compared to traditional glass. It can withstand blows that would shatter glass easily. This makes it safer in many settings, like schools and homes.

Harsh weather conditions do not affect acrylic much. It remains stable during rain, snow, and extreme temperatures.

The fracture pattern of acrylic is unique. When broken, it tends to crack rather than shatter into sharp pieces. This feature enhances safety, especially in public spaces.

Transparency and Light Transmission

Acrylic offers high optical clarity. It transmits up to 92% of visible light, making it an excellent choice for applications needing clear visibility.

When compared to traditional glass, acrylic has similar transparency levels. However, it weighs less and is easier to handle.

Its light transmission capabilities make it ideal for displays and signage. Many businesses prefer acrylic for windows and partitions due to its clarity and durability.

Uses of Acrylic Glass

Home and Interior Design

Acrylic glass is popular in home and interior design. It works well for skylights and commercial windows. This material allows natural light to brighten spaces while providing insulation.

Modern furniture often uses acrylic for its sleek look. Tables, chairs, and shelves made from acrylic are stylish and durable. Homeowners can also create unique decor pieces with acrylic. Custom designs can fit any space and style.

Industrial Applications

Acrylic glass has many uses in industrial settings. It serves as a protective barrier in factories and workshops. Retail signage often employs acrylic due to its clarity and durability. Signs made from acrylic resist weathering and fading.

Aquariums and terrariums benefit from acrylic’s lightweight nature. Builders use it to create large tanks that showcase aquatic life. Displays in commercial settings also utilize acrylic for their appealing appearance. Retailers choose it for product displays because it enhances visibility.

Art and Display Purposes

Artists frequently use acrylic glass in their work. It plays a significant role in art installations and museum displays. Many artists appreciate how acrylic can enhance the viewing experience.

Frames made from acrylic are becoming increasingly popular. They provide a clear, durable option for displaying artwork or photographs. Custom display cases made from acrylic protect valuable items while showcasing them beautifully.

Working with Acrylic Sheets

Cutting Techniques

Using Basic Tools

Acrylic sheets can be cut using simple tools. Scoring knives work well for thinner sheets. You score the surface and then snap it along the line. This method is easy, but it requires a steady hand. For more precise cuts, a Dremel tool is recommended. Dremels allow users to create intricate shapes and curves. Proper technique is essential to avoid damaging the acrylic sheet.

Knife Cutting Method

The knife cutting method involves scoring and snapping. Start by placing a straight edge along where you want to cut. Score the acrylic sheet firmly with your knife. After scoring, apply pressure on either side of the line to snap it cleanly. Be cautious; uneven edges can result if not done carefully. This technique works best on cast acrylic sheets that are less than 1/4 inch thick.

Dremel Cutting Method

Using a Dremel allows for smooth and precise cuts in acrylic sheets. Select the right attachment based on the thickness of the material. A fine-cutting wheel is ideal for detailed designs. Always wear safety goggles when using a Dremel. Acrylic can produce small shards during cutting, which may fly into your eyes. Following safety precautions ensures a safer working environment.

Thickness Considerations

Thickness plays a significant role in how acrylic performs. Thicker acrylic sheets offer more strength but less flexibility. For applications like acrylic windows, thicker materials are often preferred for durability. Conversely, thinner sheets are suitable for projects requiring flexibility, like acrylic prints or acrylic photo prints.

Choosing the correct thickness also impacts pricing. Thicker acrylic costs more due to the increased material used. Thicker sheets might require different cutting methods, such as using a saw instead of a knife. Always consider how you plan to use the acrylic before deciding on thickness.

Cost and Availability

Price Factors

Size, thickness, and quantity affect the cost of acrylic glass. Larger sheets typically cost more than smaller ones. Thicker sheets also carry a higher price tag. Buying in bulk can lead to significant savings. For example, purchasing several sheets at once often lowers the price per sheet.

Acrylic glass is generally cheaper than traditional glass. The average cost for acrylic ranges from $10 to $30 per square foot, depending on its specifications. In contrast, traditional glass can start around $15 and go much higher based on quality and thickness. This cost advantage makes acrylic a popular choice for many projects.

Where to Buy

Purchasing acrylic glass is easy with various options available. Local hardware stores often stock basic sheets and supplies. Specialty suppliers provide more variety, including custom sizes and colors.

Online retailers offer an even wider selection. Websites like Amazon or specialized plastic suppliers allow customers to compare prices and types easily. However, it’s important to check for quality and authenticity before buying. Look for reviews or ratings from other customers to ensure you’re getting a good product.

Acrylic vs. Plexiglass

Key Differences

Acrylic and plexiglass are often confused. Acrylic is a type of plastic made from methyl methacrylate. Plexiglass is actually a brand name for acrylic sheets. Both materials share many properties but have key distinctions.

Acrylic sheets are known for their UV resistance. This means they can block harmful ultraviolet rays. They also weigh less than traditional glass. This lightweight feature makes them easier to handle and install.

In many scenarios, acrylic outperforms glass. For instance, in safety applications, acrylic safety glass is much stronger than regular glass. It resists shattering better, making it ideal for places like schools or playgrounds. Clear acrylic provides excellent clarity, almost like real glass, without the heavy weight.

When to Choose Each

Choosing between acrylic and other materials depends on the project needs. Acrylic works well for displays, signs, and protective barriers. Its flexibility allows it to be shaped easily for various designs.

Traditional glass might be preferable in certain situations. For example, if you need high scratch resistance, tempered glass may be a better choice. Glass also offers superior optical clarity in some cases.

To evaluate your needs, consider the following:

- Purpose: What will the material be used for?

- Environment: Will it be exposed to harsh weather or UV light?

- Safety: Is shatter resistance a priority?

- Weight: Do you need something lightweight for easy installation?

FAQs About Acrylic Glass

Common Questions Answered

Acrylic glass is known for its durability. Many people wonder how strong it really is. Acrylic can withstand impacts better than glass. It’s about 10 times stronger than standard glass. This makes it a great choice for windows, displays, and even safety shields.

e misconceptions exist about acrylic’s transparency. People often think it is less clear than glass. This is not true. Acrylic has a light transmission rate of over 92%. It is as clear as glass. Maintenance is also easy. Regular cleaning with mild soap and water keeps it looking new. Avoid harsh chemicals to prevent scratches.

Cutting and installing acrylic requires specific techniques. Use a fine-toothed saw for clean cuts. A jigsaw or circular saw works well too. Always wear protective gear when cutting. For installation, use screws or adhesive specifically made for acrylic. These methods ensure a secure fit without damaging the material.

Additional Resources

For those wanting to learn more about acrylic glass, several resources are available. Books like “Acrylics Unleashed” by Michael Townsend provide insights into projects and techniques. Articles from reputable sources cover various aspects of acrylic use and care.

Online tutorials offer step-by-step guidance for DIY projects involving acrylic. Websites like YouTube have numerous channels dedicated to crafting with acrylic. These videos show how to cut, shape, and install acrylic correctly.

Industry associations also provide valuable information on acrylic materials. The American Plastics Council offers updates on trends and innovations in the industry. Their website includes resources for professionals and hobbyists alike.

Final Remarks

Acrylic glass is a versatile material that offers numerous benefits. Its lightweight nature, clarity, and durability make it an excellent choice for a variety of applications. Whether you’re crafting a project or considering it for commercial use, understanding its properties and uses helps you make informed decisions.

Embrace the advantages of acrylic glass in your next endeavor. Explore its potential, and don’t hesitate to reach out for more insights or assistance. Your next project could greatly benefit from this fantastic material. Dive into the world of acrylic today!